As we all know, each type of resistance devices have their advantages, and their functions are different under different circuit requirements. In this article, we will talk about why more and more people are using NTC thermistors. Read on to learn more about their advantages.

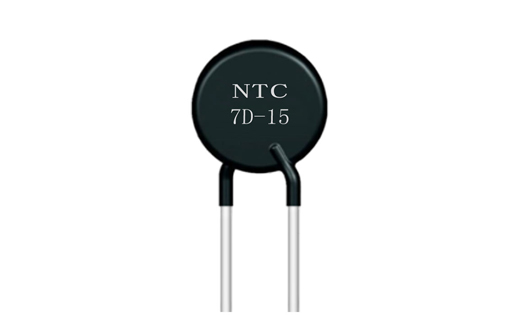

The typical characteristic of thermistor is that it is sensitive to temperature and exhibits different resistance values at different temperatures. Positive temperature coefficient thermistor (PTC) has a higher resistance value when the temperature is higher, and negative temperature coefficient thermistor (NTC) has a lower resistance value when the temperature is higher. They are both semiconductor devices.

Advantages of NTC thermistors:

NTC thermistor is a type of temperature sensor that is widely used in industrial temperature measurement. Compared with the semiconductor integrated temperature sensor, NTC thermistor has the features of wide temperature measurement range, easy to use and low price. Compared with platinum thermistor or thermocouple, NTC thermistor has the characteristics of high sensitivity, simple circuit and low price.

The Role of NTC Thermistor in the Circuit:

In the rectifier and filter circuit, in order to avoid the instantaneous surge current generated by the capacitive load charging at the moment when the electronic circuit is turned on, a power NTC thermistor is usually connected to the power circuit. This can effectively resist the surge current the moment the electronic device is turned on. After completing the function of resisting the surge current, the resistance of the NTC thermistor will drop to a very small value due to the continuous action of the passing current, and the power consumption is very small so as to be ignored, and it will not affect the normal operation of the circuit. Therefore, in the medium and small power supply circuits, power NTC thermistors are widely used to resist bootup surge current.

All in all, NTC thermistor can suppress the surge current generated by boot-up. If you have any questions about the application of NTC thermistors, you;may;consult an experienced manufacturer for help.Dongguan Zhixu Electronics Co,. Ltd (JEC) manufactures a full range of high quality thermistors of competitive price. JEC is ISO9001 and ISO14001 certified. JEC's safety capacitors (X and Y series) and varistors have passed certification of main industrial countries across the world. JEC's ceramic capacitors and film capacitors are in line with environmental protection directives.

We are often imitated but never surpassed. JEC has over 30 years experience of manufacturing ceramic capacitors. You wouldn't regret if you choose us. If you have technical questions or need samples, please contact us.

The above info is provided by the marketing and department of Dongguan Zhixu Electronics Co., Ltd.;(JEC). For more information, please visit the News section on our official websites.